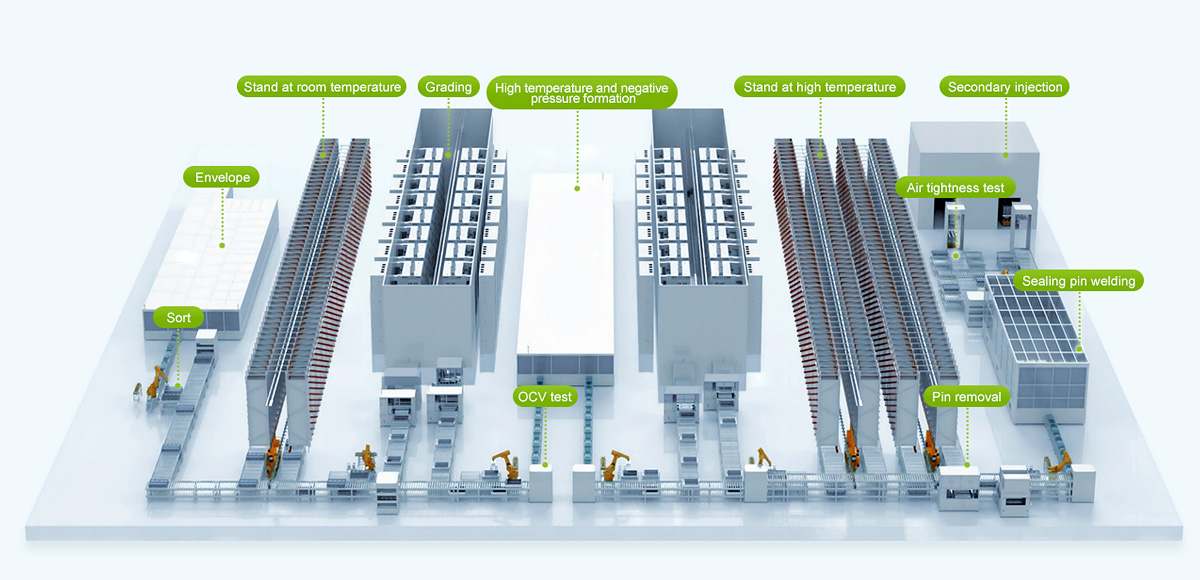

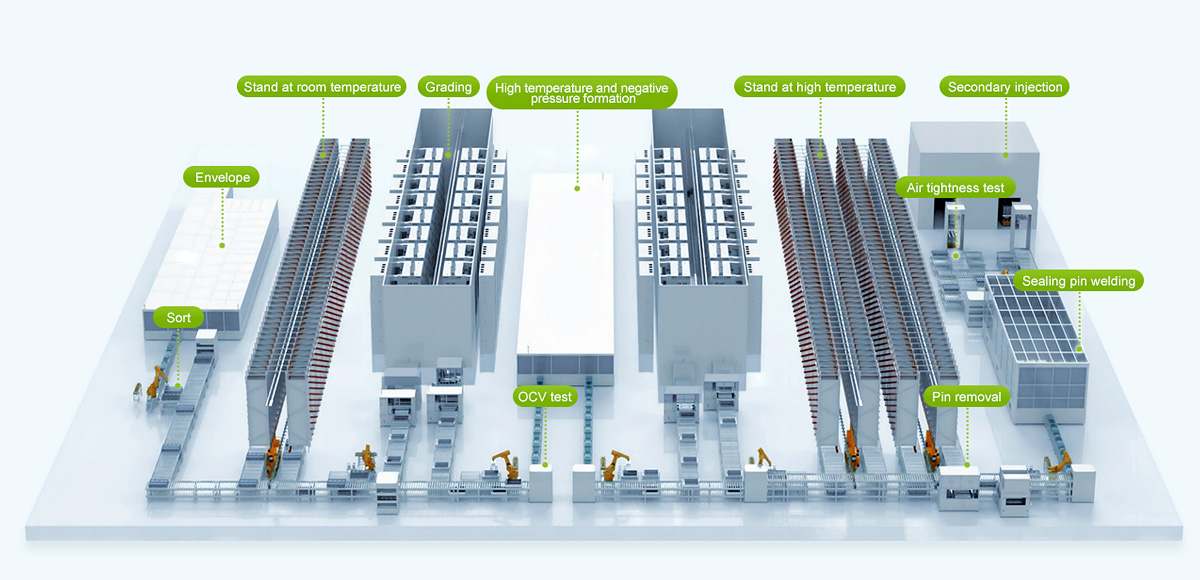

Lithium battery production line

Lithium battery production line

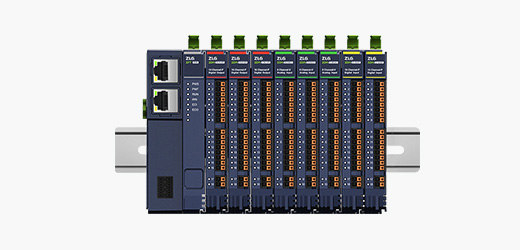

Solution of control system for lithium battery manufacturing equipment

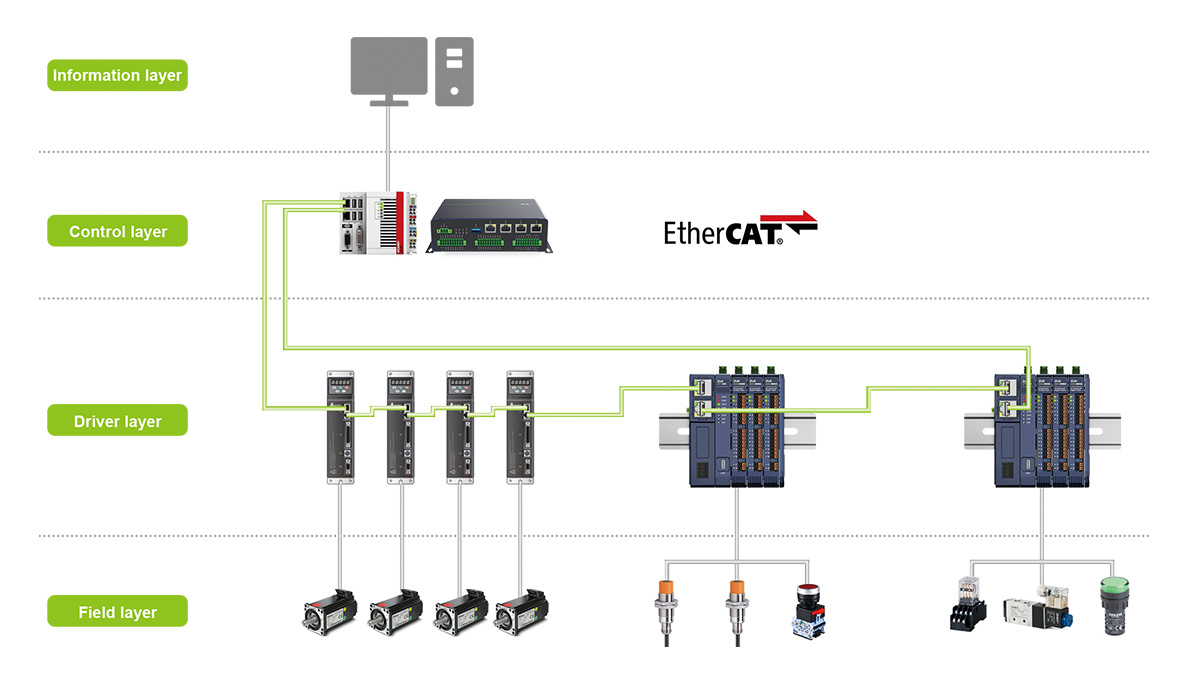

With the vigorous development of global new energy vehicle industry, lithium battery manufacturing has ushered in another period of rapid growth. The electric control system of lithium battery manufacturing usually adopts PLC as the main control of the equipment. Taking this project as an example, the system adopts Beckhoff EtherCAT logic controller as the main control, drives a large number of stepping and servo motors through EtherCAT, and uses Zhiyuan Z series remote I/O products. Remote I/O is mainly used for the acquisition of position signals of photoelectric switches and proximity switches as well as the output of control nodes of solenoid valves and relays. The adoption of high-speed EtherCAT remote I/O helps to improve the production efficiency greatly.

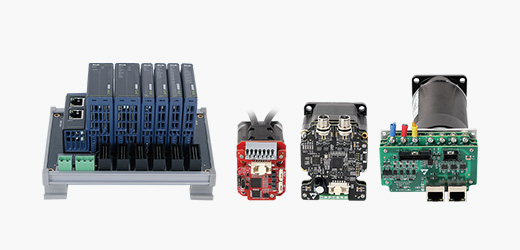

Recommendation of system products